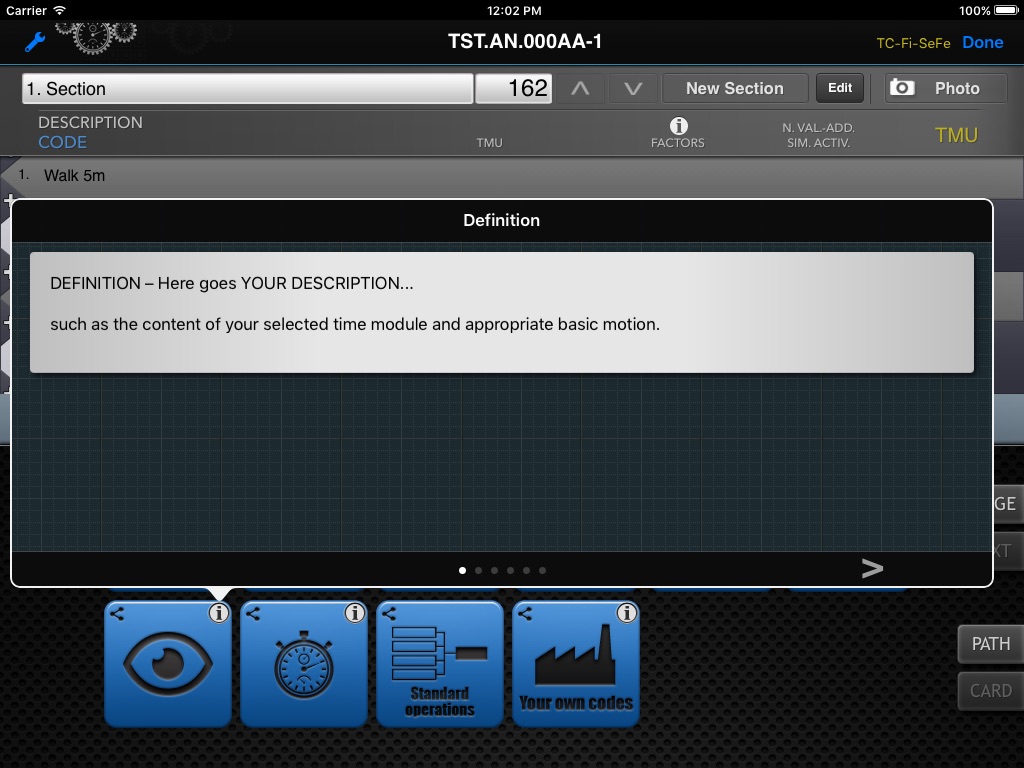

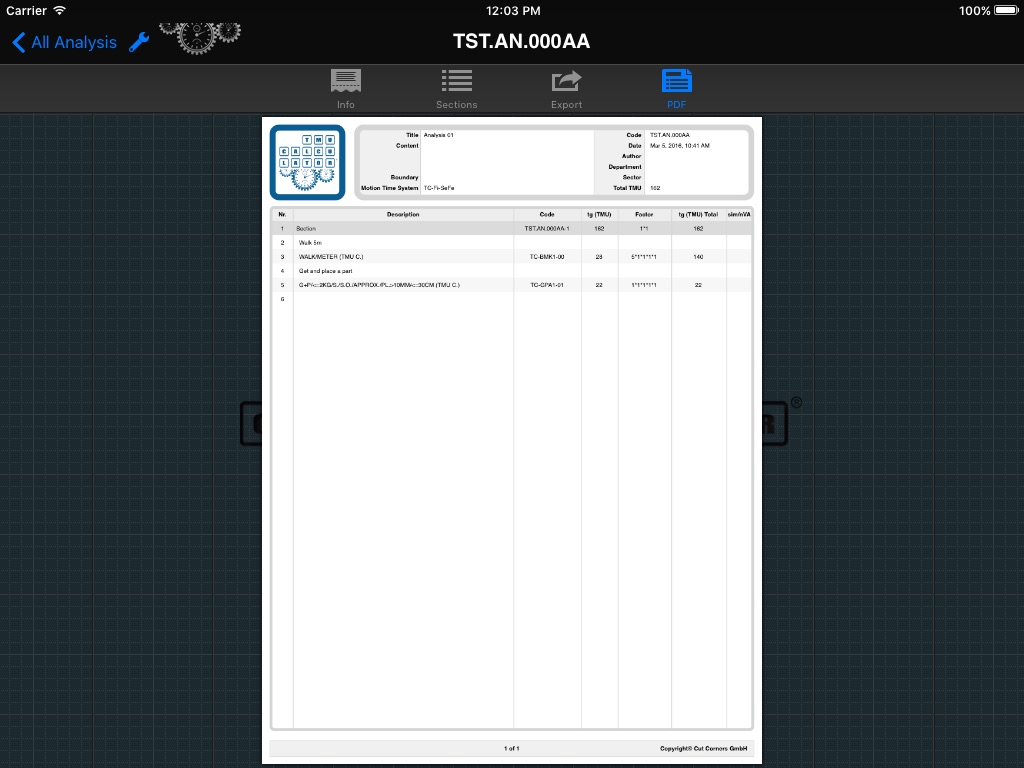

The MTM-App TMU Calculator® allows you to prepare your MTM-analyses directly on site and transfer them to your system at the touch of a button to keep the costs for MTM implementation low and profitable and is a valuable tool for training employees in the use of pre-determined time systems. The device provides a high degree of transparency through its comprehensible selection steps, stored definitions, message notifications and sets of rules. These can be viewed at any time, even during mobile device application.

The TMU CALCULATOR® finds application in individual-, series- and mass production whose areas are already valuated and should be continuously improved, or should be valuated from scratch with standardized time modules from pre-determined time systems such as Methods-Time Measurement (MTM).

The basic idea in developing an MTM application as a tablet solution was to develop a software package that’s functional and intuitive to use, and that makes the process for preparing MTM calculations more cost-effective and more comprehensible for third parties . This is why we also placed special importance on making the solution transparent to and understandable by production employees, so as to achieve higher acceptance for MTM. “Increase your productivity by using the right equipment.”

The device processes pre-determined time systems (e.g. MTM) and thus provides the user with reproducible methods that include a clear method-time relationship. It is especially well-suited for pointing out wastefulness over the entire value-added chain, lowering unnecessary costs and increasing the competitive ability.

As its productivity is greater than that of conventional analytical methods, the TMU CALCULATOR® is an optimal instrument in supporting continuous improvement processes.

The factors that drove development of the TMU CALCULATOR® were solutions that were “tried and tested” and complete. Again, these included current methods for preparing MTM analyses and process modules with different types of level II data and their compression previously: documenting processes on paper, typing this into the recording system, verifying with timer modules.)

The idea in development was therefore not to question MTM as a pre-determined time system, but rather entirely the opposite—to optimize the use of the up to now successful, and rightly so, MTM process for calculating industrial production processes. We did this by shortening the path from process monitoring on site, through documentation of individual process steps on paper, up to their representation on the PC for CIP purposes. In this way, process paths, unnecessary waiting times and quality defects could be reduced to a virtually insignificant magnitude. This in turn would lead to a high productivity increase in preparing MTM analyses.